Touch panel - PCAP vs. resistive touch and details on construction, advantage

Differences between resistive vs. capacitive touch panel (PACP)

A popular question is "What are the differences between resistive and capacitive touch?" or even "Which touch technology is better for my application?". And are capacitive touchpanel the better ones?

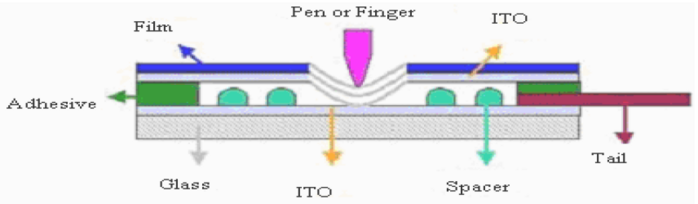

Resistive Touch Panel

"Resistive" stands for the measurement method, i.e. the measurement of a resistance and "responding to pressure".

The structure of this technology consists of two layers, usually a deformable polyester film and a rigid glass substrate. The inner sides are each coated with a thin, translucent metallization (usually indium tin oxide). In order to avoid short circuits, both layers must be kept at an even distance with so-called spacers.

If the deformable layer is now pressed from the front, contact is made with the lower layer. The position can be determined by measuring the resistance.

Measurement method:

A DC voltage is applied to one of the two plane layers, e.g. the upper one. In the non-pressed state, no voltage can be measured at the other layer.

If the two conductive layers are now pressed together at a certain point, a voltage is measured which is linear to the position of the pressure point. This allows a direction to be determined, e.g. the X-direction. In a second measuring process, a voltage is again applied, only this time to the other layer (e.g. the lower one). A voltage measurement at the other layer (top) allows a conclusion about the position in Y-direction.

In contrast to PCAP (capacitive touch panels), resistive touch panels are much more reliable in their response behavior. Where with PCAP (cell phone etc.) you sometimes try a second or third time "to hit a key", the resistive touch panel reacts immediately - provided that the corresponding evaluation is done. We have summarized further differences in a table below.

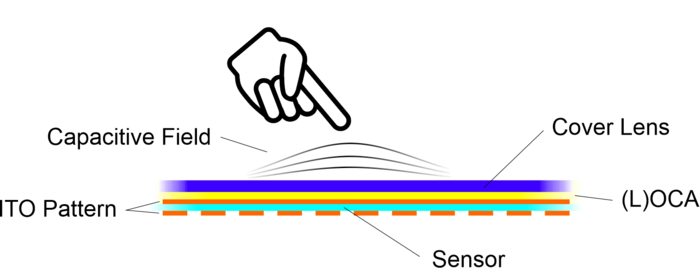

Projected Capacitive Touch panel Technology (PCAP)

Compared to a resistive touch, a (projected) capacitive one works without any pressure. It only has to be touched lightly. This technology only uses a glass plate. There is a transparent conductive layer on its back. Projected capacitive technology (PCAP) also requires two metal layers that are insulated from each other. The surface is divided into grids and the current capacity of each field is permanently monitored.

Alternating current is applied to this, creating an electric field. When a finger approaches the surface, the capacitances of the individual ITO tracks change. This can be measured and the exact position determined.

Because this conductive foil is attached to the inside of the overall construction, operation takes place on the practically wear-free and clear glass surface. However, this technology can only be operated with very thin gloves or special conductive input pens besides the finger.

In contrast to a resistive touch panel, the surface is thus much harder and virtually wear-free. A disadvantage is that water affects or even disables functionality. We have listed further differences of PCAP vs. resistive touch technology in the table below.

Which Touch is suitable for me/ my application?

Due to the physical differences, it is not possible to give a blanket answer. There are advantages and disadvantages of the individual technologies depending on the applications. In addition to the differences mentioned above, there are many other details in the design and construction that must be considered individually for each device.

The table below helps to get an overview.

Advantages and disadvantages (differences) of capacitive vs. resistive touch panels

| PCAP vs. Resistive Touch | Resistive | Capacitive PCAP |

| Operable with gloves | ++ | - |

| Operable with pen | ++ | 0 |

| Haptic | 0 | ++ |

| Surface (scratch resistance) | - | ++ |

| Robust structure | + | 0 |

| Lifetime | + | ++ |

| Input security | ++ | 0 |

| Wipe operation | 0 | ++ |

| Operation with water drop on surface | ++ | - |

| Transparency | >80% | >87% |

What is the right touch panel? Feel free to send us an e-mail with your application requirements or give us a call: we have specialists with 20 and 30 years of experience in some cases. We will be happy to compare both technologies together with you in consideration of your application.

Browse our online store for standard touch panel solutions from 1.7" to 7":

Conclusion

Resistive touch panel (RTP)

A resistive touch panel requires a slight pressure. This can be applied to the touch panel not only with a finger and glove, but also with any other object (e.g. pen or tool), thus triggering the touch panel. The biggest advantage is the reliable response.

Capacitive touch panel (PCAP)

The "projected capacitive toiuchpanel" only reacts to a "real" finger or special stylus. In return, it is clearer and can ideally be operated very smoothly. The biggest advantage is that it is not subject to wear and the possibility for an indiviual design and printig for protection glass.

© Dipl. Ing. Ralph Tischer - 05.2023

More information and links

The most elegant and simple way to use a touch panel is buying an intelligent display.

Touch panel with built-in intelligence

-> eDIP-Serie / -> uniTFT-Serie

Two series are available here: the eDIP series and the uniTFT series. Both offer an SPI interface, an I²C interface and an RS-232 interface. The touch panel is fully supported (hardware and software). Buttons, controllers or switches are defined with the simplest functions (commands) and corresponding actions are defined.

Touch panel without Intelligence (RGB / LVDS / SPI)

-> TN and -> IPS-Displays

Ideal for integration / connection to an embedded system. The display is usually controlled via RGB, LVDS or SPI. The touch panel offers an I²C bus interface. Interface boards and demo boards are available.

Touch panel as a single component

-> Touch panel in our shop

If only the glass with touch functionality is required, we stock various standard sizes from 1 piece for call-off in Gilching. Ideal for prototypes and small series.

In any case, you will receive full support directly from the manufacturer DISPLAY VISIONS / ELECTRONIC ASSEMBLY GmbH.

![[Translate to Englisch:] Inbtelligente Touchpanel, HMI oder Standard IPS Panel mit RGB oder reine Konpnenten zum Nachrüsten oder als Ersatz [Translate to Englisch:] Inbtelligente Touchpanel, HMI oder Standard IPS Panel mit RGB oder reine Konpnenten zum Nachrüsten oder als Ersatz](/fileadmin/_processed_/d/0/csm_Touch_weiterfuehrende_Links_ba1e038fbb.webp)